That said, I had a lot of fun with the whole process last night. I've done fusing a few times, but didn't really have any specific projects in mind. I made a few headpins, made some rings - but really didn't take it much further. I did discover a few little tidbits that will help you out.

1) Use a good torch. I had a couple torches at my disposal last night, and the one I like the best was a gift from Kate Mckinnon - It's a blazer brand hand held torch. While it was very similar to my micro torch, it just had that little bit of extra oommph. It seemed to me that I was able to get the silver to flow just a wee bit faster. It felt more powerful - And hey, more power is almost always better! :-)

2) Make sure you have no visible seams. Silversmiths will know this already. You can't join air together. The metal being fused MUST be flush with the other bit of metal. If you can see a gap, it most likely wont work. Save yourself some effort, and use your pliers to make sure the seams are touching with no gaps.

3) Don't try to work too big, unless you've got a really big torch. In order to get the metal to flow, the whole piece needs to be hot. It's really hard to get the whole piece hot enough with a small flame - It may work if you're persistent enough, but keep that for a later project. :-)

While we're waiting for the video, here's some pics of my workspace last night.

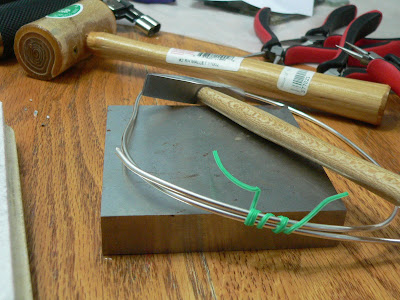

I was making a chain using handcut jump rings from fine silver wire. The gauge I was using was around 14. 12 gauge would work well for this too.

I made about 10 wraps of wire around a metal ring mandrel, and then cut the individual rings with a flush cutter. A double flush cutter would have worked better.

Ohhh - Tip 4 - Use the best tools you can afford. I once had a set of very good tools, that unfortunately my husband got a hold of - they're now rusted pieces of junk. Excellent quality pliers and cutters will set you back in the range of $30 to $85.00 per tool. Double flush cutters are definitely on my wish list.

((double flush gives a completely straight cut, as opposed to one side flat, the other pointed)

I preclosed the large jump rings I just made, and then cut a bunch of smaller rings using a smaller gauge wire (18 gauge)

You can fuse up all of the larger rings, then connect the larger rings with the smaller jump rings to form a chain. Then fuse all of the smaller links.

Once I had the bracelet links all fused together I hammered the outside, bottom and top of each ring to give it a bit of texture. The clasp that you see on the finished piece was a bit of a happy accident. I was trying for something else, and it just sort of came to be. It's a fused barbell, with a fused headpin wrapped around to form the bar. It worked well with the design :-)

These jump rings have seems - bad, bad seems!

Ahha! - We now have video. I'll post this, and then I'm signing off for the night. More fusing goodies at some point tomorrow. I'm pretty tired, and I'm not sure at this point if it makes sense to you all. Feel free to post any questions, or anything you want me to clarify in the comments below. Night all

No comments:

Post a Comment